Digitalization of production lines

V-ZUG develops, creates and produces state-of-the-art household appliances that make no compromises when it comes to sustainability and the environment. Innovative technologies, intuitive operation and minimalist design are among the main features of V-ZUG products.

For 110 years, V-ZUG has been developing and producing appliances for kitchens and washrooms in Switzerland. In the process, it has been relentlessly striving for state-of-the-art production and an improvement in the industrial eco-balance.

"Thanks to the intuitive digitalization options in iDIP, we can carry out process optimizations in production completely independently and implement them step by step without any external development effort."

Thomas Glauser - Process Analyst V-ZUG

Challenges at V-ZUG

- Very large product variety e.g. more than 650 oven designs.

- Assembly workstations exhibit different levels of automation (from pure manual labor to fully automated robots) and must function and cooperate smoothly with each other.

- High quality requirements at the workstations.

- The production lines and workstations are continuously adapted and optimized. Thus, adjustments by external service providers of the systems used are necessary again and again (causes costs and coordination effort).

- Continuous new digitization needs, which are very costly and time-consuming to implement with the appropriate responsible parties.

- Fail-safe, redundant production operation with a completely traceable sequence of production control.

Implemented Functionality

- Line management (workstation management)

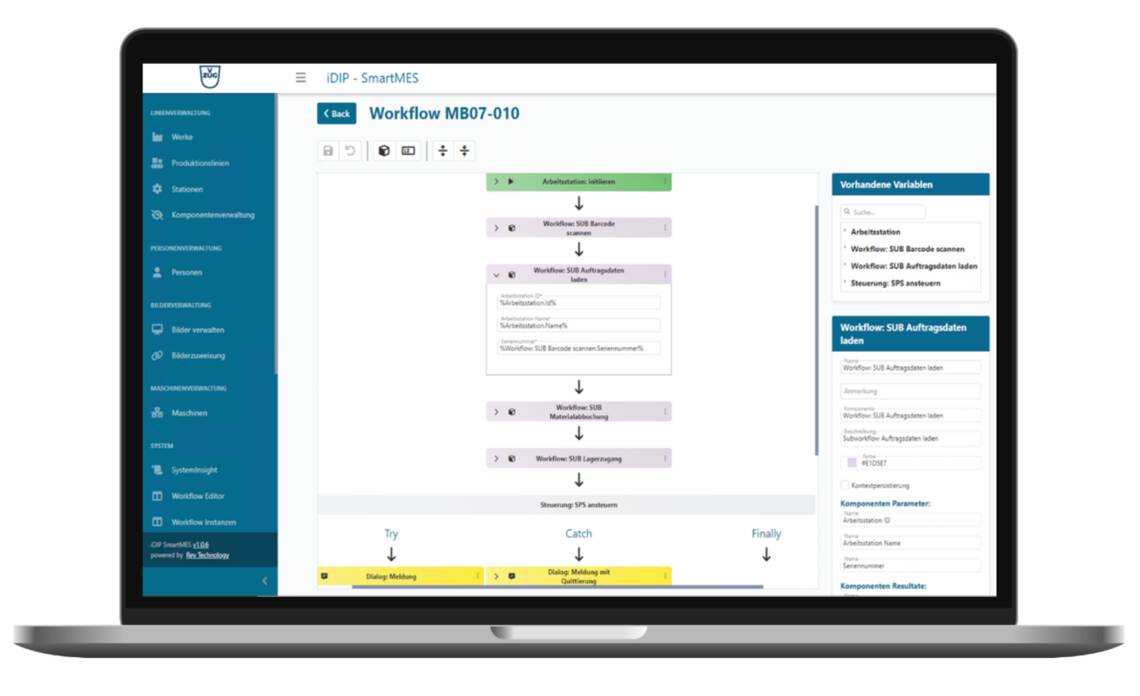

- Workflow management (batch processing, process control)

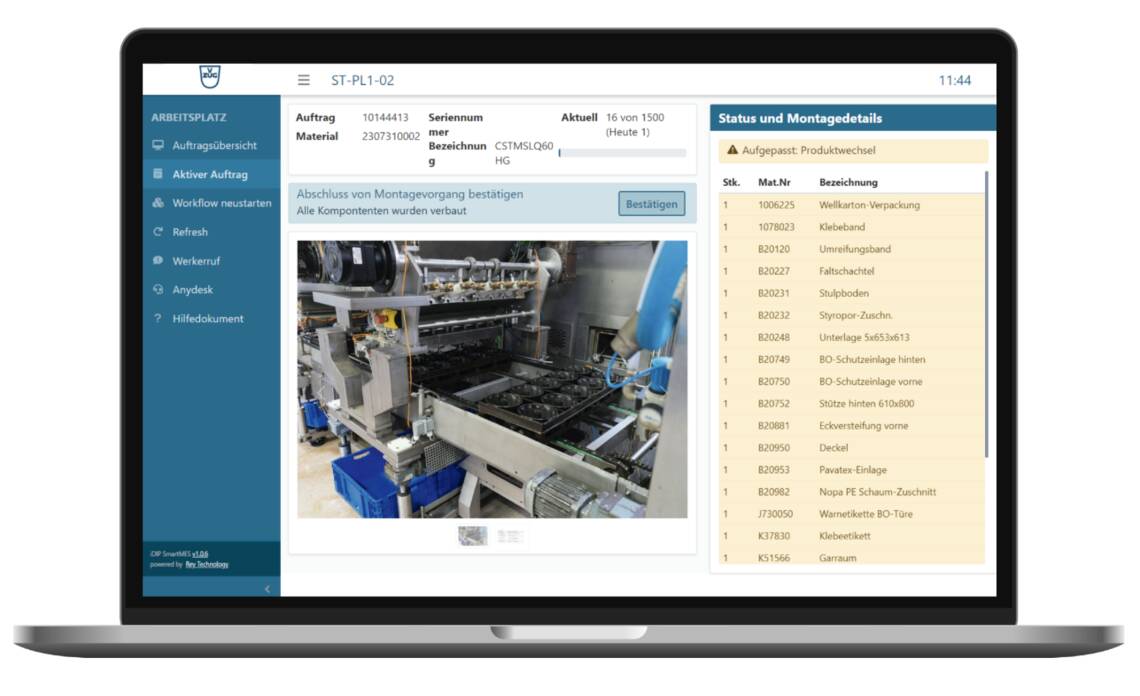

- Assembly guidance and support (images, inspection points, bill of materials, ...)

- Recipe management

- Component management (components and images for instruction instructions)

- Factory call for fast, dedicated support assistance for workstations

- System insights (traceability of production control sequence and traceability)

- Connection of peripheral systems (e.g. SAP for production orders)

- Integration of identity providers via Microsoft Azure AD

- Integration of redundant production operation

Targeted Results

After the implementation of the project with Rey Technology:

- More than 100 assembly workstations were digitized so that employees are guided individually per workstation through the assembly process with optimal support (assembly instructions, order overview, parts lists, quality check points and automated ERP bookings).

- The orchestration at the workstation (and across workstations) takes place via so-called workflows, which, in addition to process control at the individual workstations, also allows access to machine information (read and write) and peripheral systems.

- The configuration of the processes as well as the machine connections can be created, adapted or optimized independently by the plant managers. Among other things, the 100 workflows were recorded completely independently by V-ZUG.

- Connections to new peripheral systems and to new digitization processes havebeen massively simplified and are already being carried out by V-ZUG today. With the future App Designer, entire applications can be configured by the V-ZUG team.

- Due to the chosen solution and architecture, the system is now used as V-ZUG's central digitization platform in production.

Performance Overview

Technologies Used

iDIP Digitization Platform - idip-solution.com

Solution Provider

Rey Technology

Rütihofstrasse 6

CH-8370 Sirnach

Services Solution Provider

- Requirements elicitation with workshops

- Conceptual design of the solution

- Implementation of the concept with iDIP

- Hardware and software integration into the architecture of V-ZUG

- Integration of identity provider via Microsoft Azure AD

The detailed version of the post can be found HERE

Contact us

We will be happy to tell you more about the possibilities iDIP opens up for you.

Let's get in touch and find out more...

Chris Tuchschmid | Customer Success Manager iDIP