Digitized production

Güntensperger Käse AG

The challenge - separate data and media breaks

For over 130 years, Güntensperger Käse AG in Toggenburg in the canton of St. Gallen has stood for the highest art of cheese-making, rooted in tradition and characterized by craftsmanship. The family business has grown steadily and today comprises more than 40 experts and cheese professionals in three cheese dairies. Güntensperger Käse AG exports throughout Switzerland, to Germany, Austria, Italy, the UK, Ireland, Scandinavia, the USA, Dubai, Singapore, Israel, Spain, France, Australia and other countries, and describes itself as a professional in packaging and logistics.

Even in this traditional industry, the demands are increasing. Traceability, quality assurance, efficiency and transparency are key issues today. At the same time, the shortage of skilled workers is presenting many companies with additional challenges. What's more, relevant production and quality data is often available in different formats - such as PDF, Excel or paper - and in isolated data silos. This fragmentation makes it difficult to gain a holistic view of the processes and prevents efficient evaluations.

The aim was now to digitally record and evaluate all production data - from milk delivery to the finished cheese - and make it usable.

Implementation with iDIP - production planning and quality management

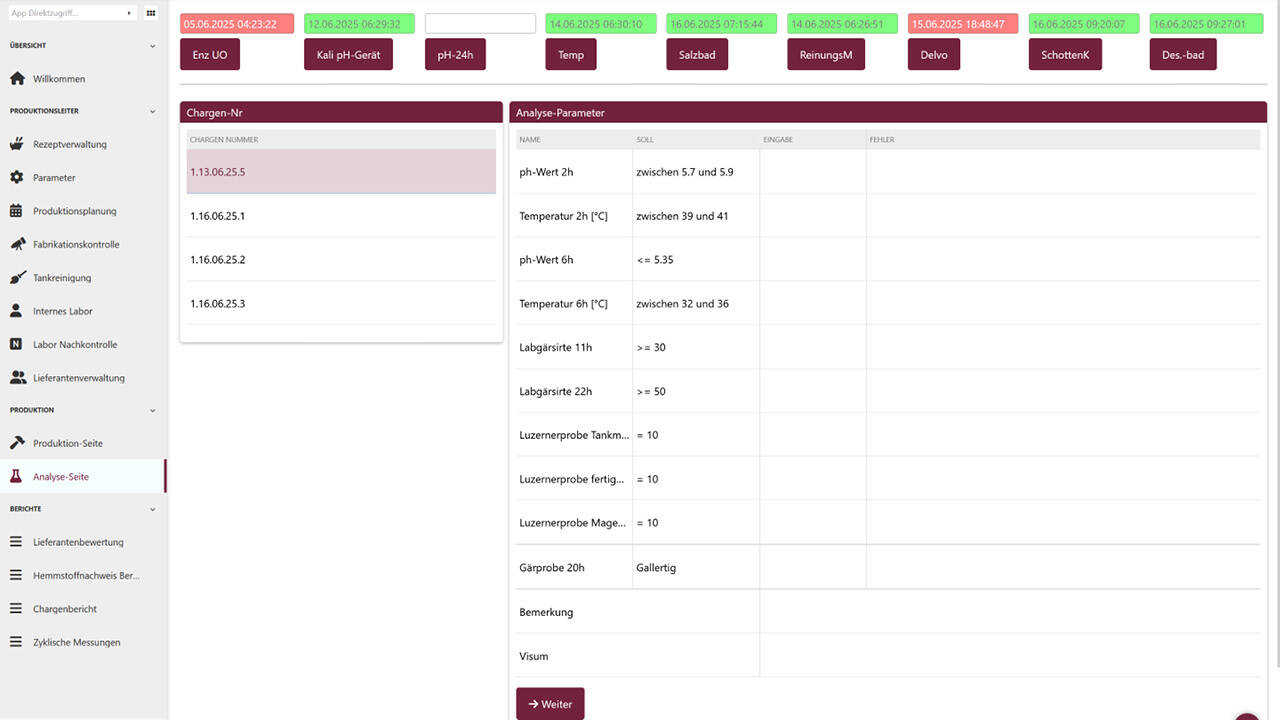

The following main functions were implemented with iDIP:

-

Factory control: digital recording of production data via tablet directly on site.

-

Test equipment inspection: Test results from the regular inspection of pH measuring devices or temperature sensors are digitally recorded on the tablet with a time stamp and archived in a traceable manner.

-

Traceability: Milk origin, batch data and laboratory data of a product are fully traceable.

-

Supplier evaluation: Laboratory results are automatically evaluated and assigned to the respective suppliers for continuous evaluation of raw material quality.

-

Production planning: Integrated planning enables precise control of processes and improves communication in multi-shift operation.

-

Laboratory: Laboratory data including follow-up checks are recorded digitally. Suppliers are automatically informed by text message in the event of anomalies or improvements.

-

Quality management: Quality data is collated centrally, problems are identified at an early stage and audit requirements are reliably fulfilled.

The result - gains in efficiency and transparency with continuous quality monitoring

The data silos have been completely dissolved so that all information is now bundled on one platform. Employees record production data directly on site using a tablet. iDIP guides them intuitively through the process, reminds them of checkpoints and documents everything automatically. This increases data quality and takes the pressure off the team on a day-to-day basis.

The integration of laboratory data offers particular added value. Abnormal values are automatically detected and the relevant suppliers are informed. This creates transparent, continuous quality monitoring.

"Our employees record the data directly with tablets. This saves time and increases accuracy. Our quality data used to be scattered in PDFs, Excel files or even on paper, isolated in data silos. Evaluation often took hours. Today, we can do this in just a few minutes with the new solution - automated, centralized and evaluable at any time.

Digitalization is not an end in itself, but it helps us to improve our craft, conserve resources and meet the increasing demands of national and international audits."

Marcel Güntensperger, Head of Technical Department

Simply get started

Get to know the Smart Factory solution of the future! We would be happy to show you the benefits you can achieve in your company.

Tomy Mändli