Digitized order and quality management

Sager AG

The challenge - replacing manual order entry and improving quality management

SAGER is the Swiss premium brand for innovative thermal and acoustic insulation. First-class insulation and various applications with outstanding insulation values have been manufactured in Dürrenäsch, Aargau, since 1949. SAGER applications meet the high requirements, for example for building to the Minergie standard, either as a standard cut or as a tailor-made individual solution.

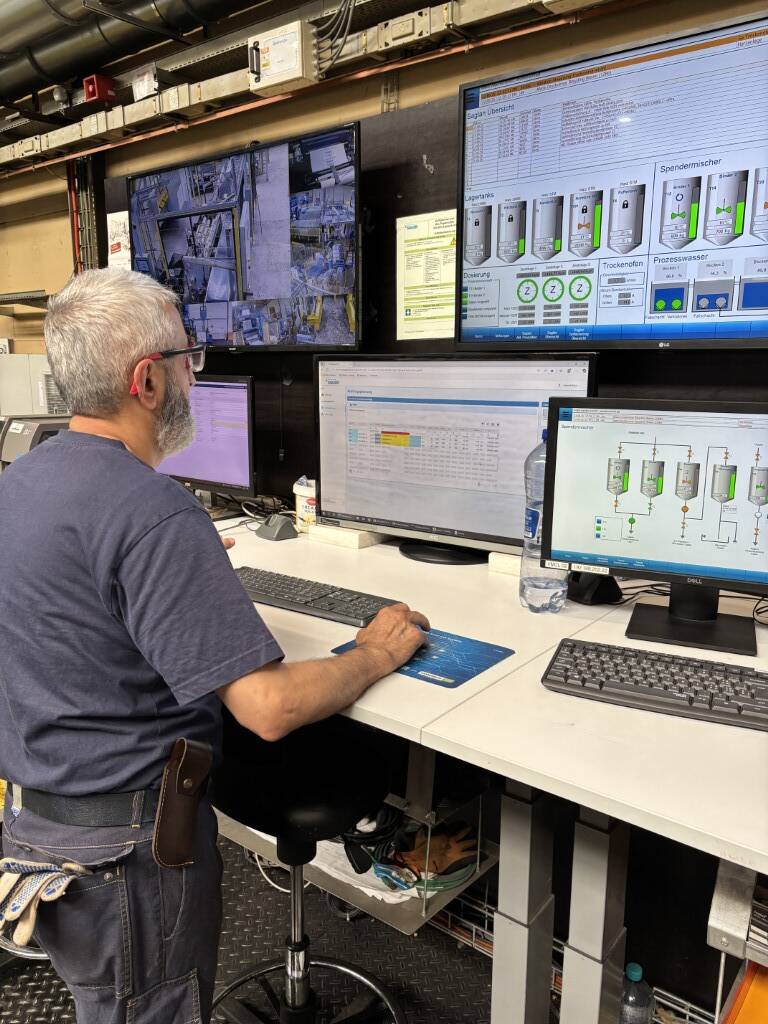

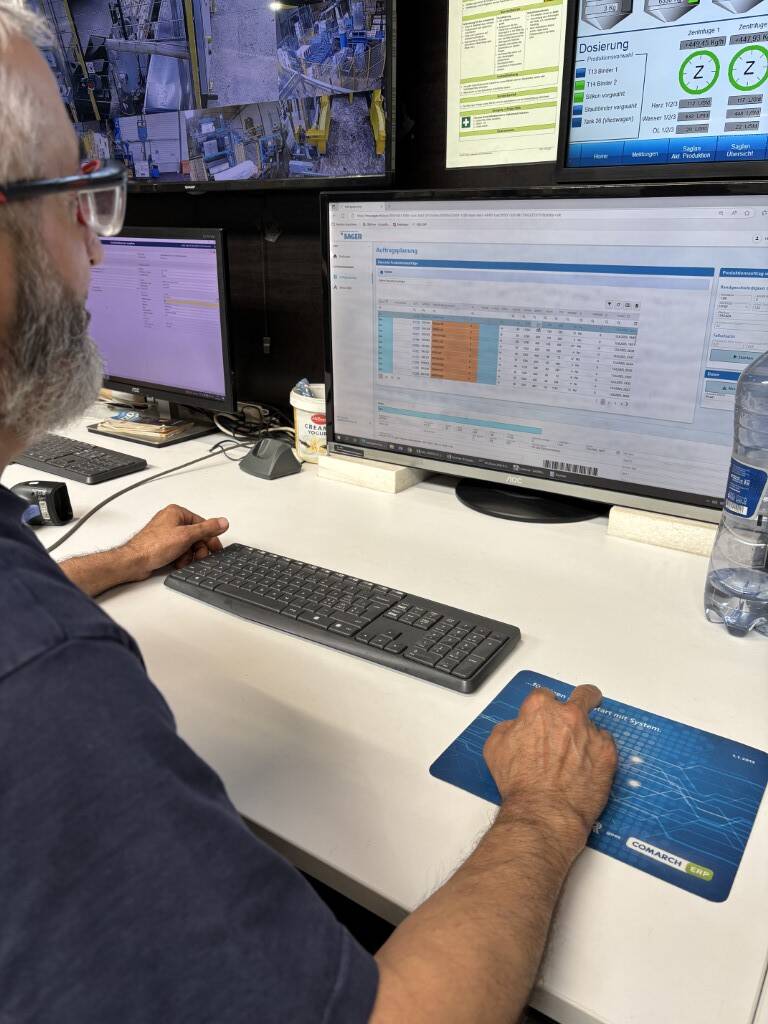

To reduce the workload of shift supervisors, order management in production is to be connected directly to the ERP so that time-consuming manual entry of order-related data in the production system is no longer necessary. In addition, quality management is to be expanded to include the option of creating digital inspection reports, which will now also include the automatically read-out actual machine data, among other things.

Implementation with iDIP - direct production of customer orders and quality management in the process

The following main functions were implemented with iDIP:

-

ERP interface: The orders are imported into the iDIP via the ERP interface

-

Calculations: individual order data such as quantity are calculated automatically based on the calculation formulas predefined in the iDIP

-

Detailed planning: the shift supervisor can define the order sequence in the iDIP and make adjustments in the iDIP at short notice even after the data is already in the production system

-

Start production: iDIP transmits the relevant data for the start of production directly to the production system that controls the machines

-

Define test reports: The laboratory manager can define in iDIP which orders and how many samples must be tested as part of the quality management process.

-

Create inspection reports: The shift supervisor is supported during inspections in ongoing production with iDIP on the tablet and the automatic printing of barcodes. The required ACTUAL values can be entered directly and a comparison with the TARGET value is made immediately.

-

Machine ACTUAL values: The machine data is recorded continuously in order to compare the ACTUAL values with the TARGET values on an ongoing basis. This comparison is included in the test reports for comprehensive quality control. If the test reports are successful, orders are automatically released for packaging & dispatch.

The result - gains in efficiency, speed and consistency as well as a new quality management process

Thanks to order management without media discontinuity, the production process is paperless and therefore significantly more robust. On the one hand, this makes order processing more efficient, while on the other, faster error detection with a prompt response leads to cost and time savings. Data storage is now centralized and therefore available to all persons involved in the process at any time as required. The result is an end-to-end process without media disruptions.

With the new quality management process, the definition and creation of test reports are now completely digital and therefore faster, more efficient and more transparent. As a result, any deviations are identified at an early stage and potential additional work is prevented.

"As we make adjustments in iDIP independently, we can react quickly to the needs of shift managers and continuously increase efficiency in order processing and quality management. This is how we are achieving our digitalization goals step by step with iDIP."

Marc Loosli, Head of Maintenance & Project Manager Plant Digitalization at Sager AG

Simply get started

Get to know the Smart Factory solution of the future! We would be happy to show you the benefits you can achieve in your company.

Tomy Mändli