Microfibrillated nanocellulose and AI in industrial manufacturing

Technikum Laubholz GmbH - Project KIckBio

The challenge - digital platform for machine data, recipe management, simulation and AI

The Technikum Laubholz (TLH) develops sustainable technologies for the use of hardwood and other renewable raw materials with the aim of shaping the industrial transformation towards a defossilized and regionally anchored economy. The focus is on sustainable materials, biotechnology, plant polymers and the integration of AI and automation.

In the KIckBio project, TLH is researching an innovative process for the production of microfibrillated nanocellulose (MFC). One aim of the project is to set up and operate a fully automated pilot plant for the production of MFC.

A digital twin of the plant maps the entire process using a real-time simulation model. In combination with process optimization through the use of artificial intelligence, the efficiency of the plant is increased

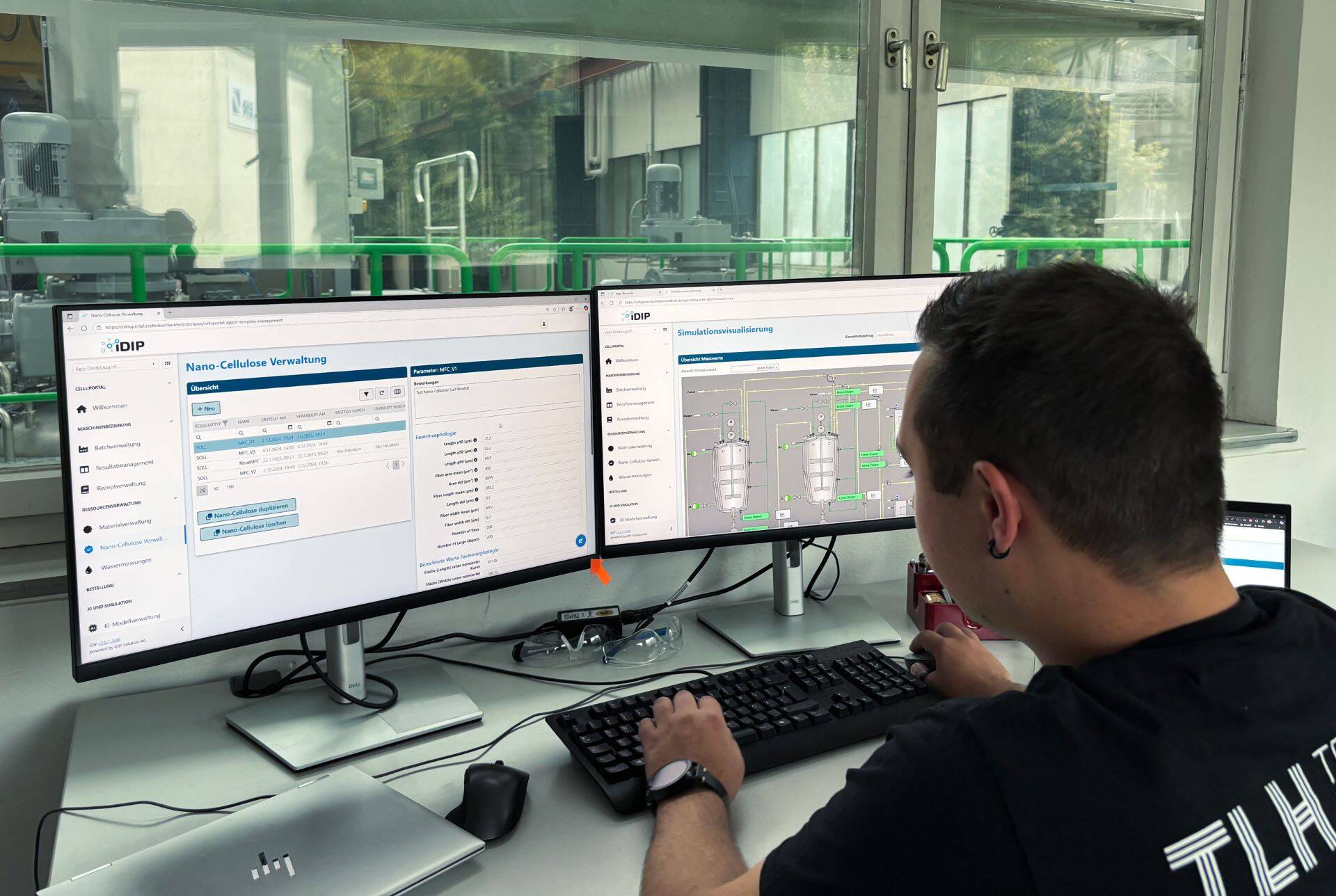

The Celluportal platform will enable plant operators, developers, AI experts and customers to control and monitor the production process in one interface. The architecture is designed in such a way that it can be easily transferred to other systems and development projects as a platform concept.

The implementation with iDIP - networking, simulation and AI in the Celluportal

Together with iDIP Solution and ITficient, the following main functions were implemented in the Celluportal:

-

Real-time machine data acquisition: Automatic import of production data from the plant control system via a data gateway.

-

Central data storage: Structured storage and management of all relevant production, laboratory and simulation data.

-

Recipe management: Creation, adaptation and transfer of new production recipes directly to the system.

-

Digital process simulation: Mapping of nanocellulose production in simulation models to test and optimize processes.

-

AI integration: Integration and training of AI models with field and simulation data to improve quality and efficiency.

-

Visualization & Reporting: Intuitive user interface with real-time monitoring, metrics and automated reports.

-

Platform architecture: Transferable system design for flexible use in future projects.

This modular system architecture allows uniform control, visualization and optimization of the entire production process within the Celluportal.

The result - efficiency, transparency and sustainability

With the Celluportal, TLH now has a powerful platform that combines plant control, simulation and AI applications in one integrated system. This means that production processes can not only be automated, but also continuously optimized based on data. The digital twin makes it possible to test changes virtually in advance, which shortens development times, reduces waste and increases production quality.

The central database ensures a high level of transparency and facilitates collaboration between operations, development and research.

The success of the project was awarded the Bioeconomy Innovation Prize Baden-Württemberg 2024, in recognition of the combination of sustainability, digitalization and innovation.

"Complex tasks can be solved well in cooperation with competent partners - this is how the Technikum Laubholz GmbH team in the KIckBio project, together with the project partners iDIP Solution and ITficient, achieved a decisive milestone for the automation and optimization of the production of microfibrillated cellulose. The close collaboration has made it possible to overcome technical challenges efficiently while establishing a future-proof platform."

Dr.-Ing. Wolfgang Wenzel, Project Manager KIckBio

Simply get started

Get to know the Smart Factory solution of the future! We would be happy to show you the benefits you can achieve in your company.

Tomy Mändli